Using Cimex or Rotary Machines to Clean Carpet? Here’s Why You Shouldn’t.

Recently I met a floorcare professional who had just struck out on his own after being employed as a technician for about 15 years. He had purchased a truckmount along with most of the essential pieces of equipment needed in commercial floorcare. However, one of the pieces he was missing was a Counter Rotating Brush (CRB) machine which he was very familiar with and accustomed to using on his previous cleaning jobs. Seeing his potential, and believing that the CRB is one of the most valuable weapons in a floorcare technician’s arsenal, I offered the use of one of my CRBs until he could acquire his own. He was very appreciative.

From this interaction, our conversation turned to other tools of the trade, including the Cimex and rotary machines in general. We discussed their role, if any, in the carpet cleaning process, and I’ll tell you what I told him – they have no place in commercial carpet care. Absolutely none!

I’ve seen the statement claiming the Cimex is the “King of Encapsulation”. I respectfully disagree. The true king of encapsulation is the CRB, specifically the style that is produced by Rotowash in Europe and has been exported around the world and across the U.S. by R.E. Whittaker Company and Carpet Cleaner America. When it comes to encapsulation cleaning for commercial carpet, the CRB is simply legendary. This has been the case for decades and will continue to be for the foreseeable future. A CRB is an acceptable alternative to a certified pile lifter and is the most versatile cleaning tool at our disposal.

Not Designed or Recommended for Textile Flooring

Here’s the problem with the Cimex and rotary types of machines being used on commercial carpet. The Cimex was originally designed to clean and polish hard surfaces, specifically stone. The planetary action of the machine (along with the weight of the machine itself) creates power, friction, and heat during the cleaning process. Is that what we want (or need) on commercial carpet – weight and friction? No, thank you! Additionally, 175 rpm floor machines used for agitation (either brush or absorbent pad) are heavy, durable, powerful, and aggressive. On commercial carpet, they can be unforgiving. Again, is this what we want to use on textile flooring, a piece of equipment that’s original purpose was for cleaning hard or resilient surfaces?

I’ve been very fortunate in my career to work directly with technical reps from various carpet mills, flooring experts from independent testing laboratories, and industry icons like Bob Deweese, and they all agree – horizontal agitation, whether brush or absorbent pad, should not be used for commercial carpet cleaning. In addition, no leading commercial carpet manufacturer recommends using rotary equipment or a “Bonnet” cleaning method – not Shaw, Mohawk, Mannington, Milliken, or Tarkett. In fact, they discourage the use by warning that it may void the warranty. More recently, manufacturer guidelines actually prohibit the use of all rotary type equipment.

I believe we may soon see a more comprehensive definition of rotary from the manufacturers, Carpet & Rug Institute, or the IICRC. Something like,

“Rotary Cleaning Systems are defined as cleaning apparatus equipped with a spinning, orbiting, or horizontally oscillating head which may or may not include a brush, pad, or bonnet, and is specifically designed to clean carpets. The machine may utilize water or a cleaning solution which can be ejected through jets or sprayed onto the carpet surface using alternative methods.”

Not CRI Approved

The Cimex is not CRI approved and probably couldn’t achieve a bronze level rating or pass the appearance test. Here’s why.

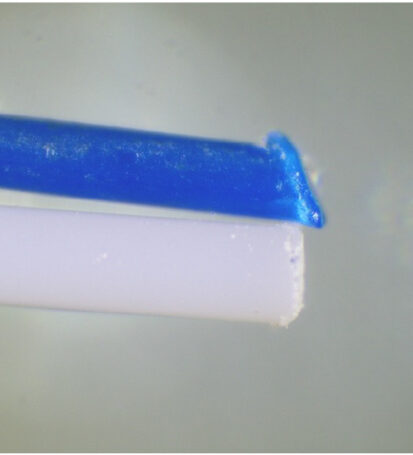

First, its carpet brush material is nylon. Yes, nylon. Basic floorcare training teaches nylon brushes are used for hard surfaces. Why? Because nylon is hard! For carpet, polypropylene brushes are to be used. It’s a softer material with a lower abrasion resistance and melting point. Because of this, the potential for damage to the nylon carpet fibers is lessened.

If you’re using a Cimex on commercial carpet, consider this scenario – two nylon fibers (brush and carpet) with similar hardness working against each other with silica in between. Which fiber is going to take the damage? Common sense dictates the carpet will. “But I pre-vacuumed. There is no silica.” Yes, there is. As a floorcare “professional”, please do not debate this. Trust me, you will lose.

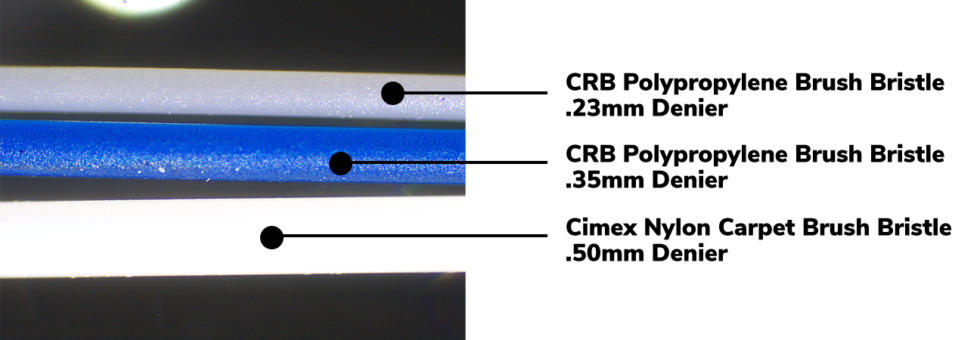

Second, based on my measurements of several bristles, the denier for the Cimex’s “carpet scrubbing” or “shampoo brush” is approximately .50mm. I’d be surprised if a manufacturer gave its blessing to use this brush on any of its textile flooring products! I believe Whittaker’s most aggressive brush for the CRB, yellow, is only about a .40mm denier and it’s a polypropylene brush only recommended for one-time restorative or salvage cleanings.

The reason for using nylon and such a heavy denier for the Cimex brush is due to the weight of the machine itself. Remember it’s intended purpose is stone polishing and anyone that knows about stone or concrete polishing knows weight is needed to process that type of floor efficiently. Any softer brush material would need to be a heavier denier to support the weight of the machine.

Unacceptable Brush Denier

Regarding brushes and how they work (this is a topic that needs more attention, so I’ll save it for another article, but here are some of the basics) – the heavier the denier of a brush, the deeper the clean. Read that again – not a better clean, a deeper clean. For a general cleaning, use a medium denier and for a superficial cleaning, the lightest denier brush possible. However, different denier brushes are not an option for the Cimex or most heavy rotary type cleaning systems. Softer materials and smaller deniers wouldn’t be able to support the weight of the machine. It’s not that the brush is doing a bad job. It’s doing what its intended purpose was – deep cleaning.

Other third-party manufacturers may make polypropylene brushes for rotary with acceptable deniers, however there’s still the problem of pile distortion and crushing from the weight of the machine. Using it is counterproductive to increasing the longevity and improving performance of the carpet. Nowhere is it written in any guideline or standard about scrubbing, crushing, or distorting the pile at any point in the cleaning process. Yet there’s multiple sources referencing “pile lifting” (i.e., pile preparation before dry soil removal, its use for actual dry soil removal, agitation during wet or various low moisture cleaning methods, and pile grooming or setting after water extraction).

Denier Comparison

Ineffective Results from Pads

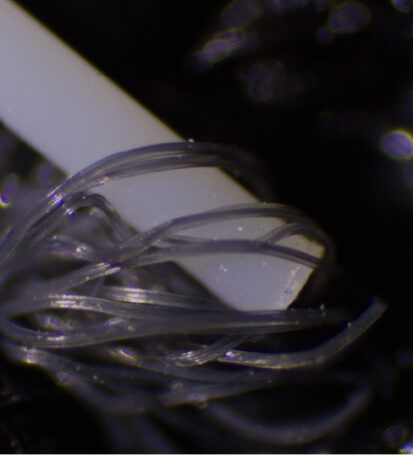

Beyond brushes, there are rotary systems that use synthetic and absorbent pads. I’ve read, “You’ll have better agitation because rather than slippery brush bristles sliding across the carpet’s surface, you’re making full pad contact with the carpet pile”. I’ll agree with one aspect. It is “better” agitation in relation to more surface contact with the face fibers. However, the “slippery bristles” are not “sliding” across the carpet’s face fibers. Exactly the opposite. The bristle tips are penetrating to the carpet backing. Therefore, they’re making minimal contact with the face fibers. Not to mention, there’s actually less fiber agitation because of the size difference in the bristle denier compared to the denier of the carpet fiber. Again, let me ask, what manufacturer is going to okay cleaning their carpet with these pads? I’d get it in writing! Even though these pads are polypropylene, they’re not equivalent to a CRB polypropylene brush. Period.

Absorbent pads (bonnets) are typically cotton or a cotton blended material in either a loop or string construction. We can all agree that cotton is a very absorbent, soft, and non-abrasive natural fiber which makes it perfect for capturing liquids in the capillary action of wicking. However, soil is roughly comprised of 75% insoluble material with silica and silicates comprising roughly 30-40% of that. When the soil is wicked into the strands, the silica embedded fibers become nothing more than sandpaper. If you have ever seen a piece of plexiglass that has been scratched, you know light doesn’t go through it clearly. Similarly, synthetic carpet fiber is a plastic, and when it becomes abraded, it dulls out and doesn’t give the appearance it once had.

Risk and Liability

As a floor care professional with over two decades of experience, I know how the blame game is often played and any flooring issues that arise automatically default to being the “cleaner’s” fault. If you’re a business owner utilizing Cimex and rotary machines on carpet, why in the world would you ever take on more liability than you must? By using equipment (or chemistry) that is not approved by the manufacturer or the CRI, you’re giving them latitude to void your customer’s warranty and walk-away, leaving you accountable for the damages and with an unhappy customer.

Conclusion

How to clean commercial carpet properly is not a secret. Follow the manufacturer’s guidelines as close as possible in conjunction with the IICRC’s S100 Standard for Professional Cleaning of Textile Floor Coverings and R100 Reference Guide for Professional Cleaning of Textile Floor Coverings. The Carpet & Rug Institute is another source for approved equipment and references, like the CRI 204 Commercial Carpet Standard for Maintenance & Cleaning.

Currently there are a few CRI approved rotary (horizontal action) pieces of equipment. However, in the CRI 204, page 17, it is stated, “Rotary or orbital cleaning equipment could negatively affect the warranty on your commercial carpet. Check with the carpet manufacturer before use of this equipment.”

Let’s be honest. We ALL know why these machines or systems are being used for carpet maintenance. They’re less expensive and the real reason for using them is productivity. The first thing any Cimex users says is, “Have you ever used a Cimex? It’s fast.” This benefits the technician or floorcare company far more than the customer. “I’ll do it faster and cheaper.” Really? But, at what cost to your customer?

Again, with the recent changes in the manufacturer’s guidelines, I expect these few remaining CRI SOA certified systems to soon disappear. Why? Because when it comes to commercial carpet care, the bottom line is do the right thing and do no harm.