Using Dry Soil Removal and Encapsulation to Target Deeply Embedded Soils on Flotex

In this snapshot of the quarterly maintenance process at a customer’s facility, Infinite Floorcare combines dry soil removal with the Fast Foamer System’s low moisture encapsulation to effectively and efficiently clean Flotex. This textile product, with the durability of resilient flooring, is maintained at peak performance and appearance even under heavy soiling, eliminating the need for water extraction.

Job Scope:

- Environment: Medical Pediatric, one of three serviced locations

- Sq Ft: 4,060 sqft (less furniture not moved)

- Flooring: Forbo Flotex

- Service Frequency: Quarterly

System, Method & Tools:

- Primary: Fast Foamer System w/ High Energy Foam, CRB debris trays

- Vacuum: Windsor Versamatic 18

Pre-vacuuming

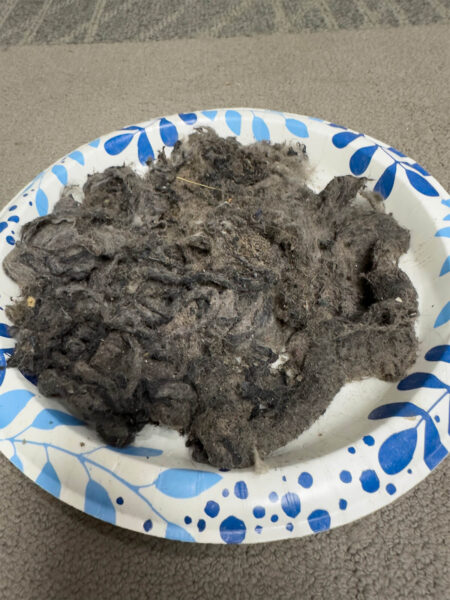

During the dry removal phase, pre-vacuuming removed 95.12 grams of dry insoluble soil. The photos show this soil with an emphasis on the finer minute particulates which is to be expected for this cleaning stage.

Encapsulation (Captured Insoluble Soil)

The photos show a combination of insoluble soils collected during the encapsulation phase with the CRB using the Fast Foamer System by Foaming Floors. Totaling 54.42 grams, the soil most notably contains deeply embedded, larger particulates that the vacuum couldn’t remove.

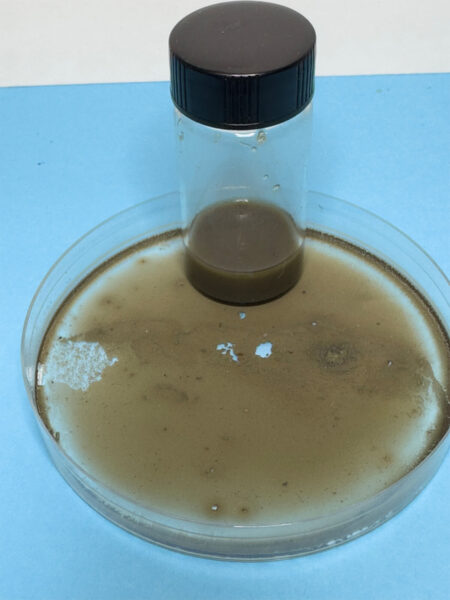

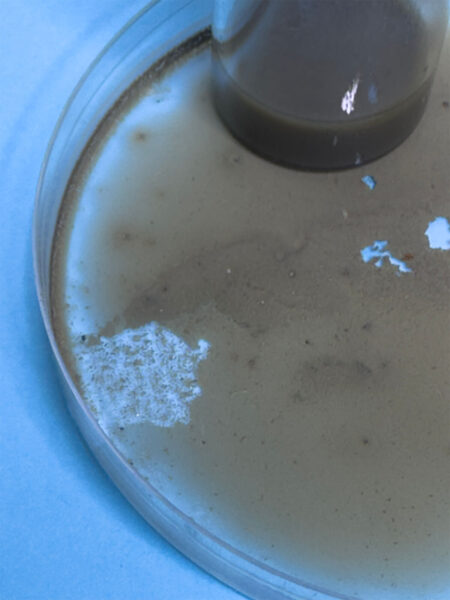

Soil Suspension

The photos show encapsulant solution squeezed from the insoluble soil removed by the CRB during the encapsulation phase. First, observe the color difference between the liquid and the crystallized encapsulant in the petri dish. Note the contrast between wet and dry, and understand that the darker color of the recovered suspended soil does not directly indicate the amount of soil removed.

Second, note how the encapsulant effortlessly suspends the soluble soils (water and dry solvent soluble soils which account for 20% of a built environment’s soil composition).

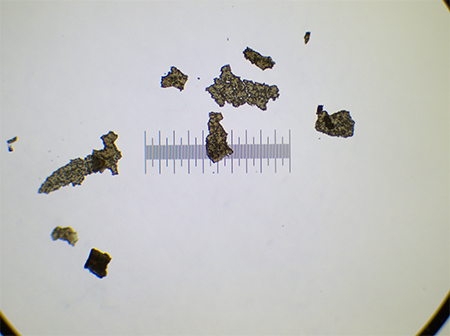

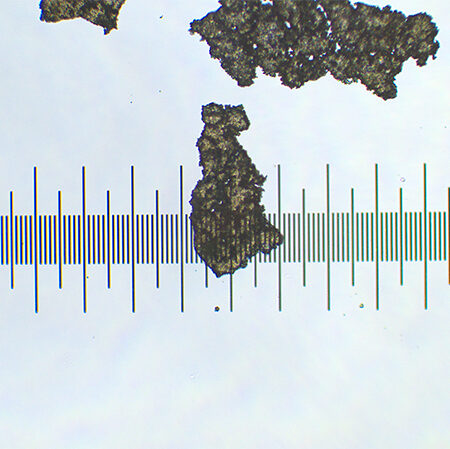

The photos show some of the ultra-fine, crystallized polymer fragments scraped from the petri dish. Under the microscope at 400X magnification, the photo reveals no visually distinguishable insoluble soil particulate, which suggests the encapsulated soil is in fact soluble soils.

Post-vacuuming

Post-vacuuming was performed by the customer’s janitorial or routine maintenance provider.

Customer Perspective

The previous office manager, overseeing all three locations, thought that the impressive results after only two cleanings warranted reducing maintenance to semi-annual or as needed, moving away from our suggested minimum of quarterly cleaning. In contrast, the new office manager, aiming for a proactive maintenance strategy while mindful of budget, accepted our advice and restored the quarterly cleaning schedule, adhering to our recommended minimum frequency.

Further Observations

Reflecting on the dry removal phase, the three-month interval between our visits may be a factor in soil accumulation. This, coupled with possible issues with the facility’s vacuuming routines, such as the type of equipment used or the frequency of cleaning, could contribute to the buildup of dry insoluble soil. Although we advise our customers on optimal vacuums, vacuuming frequency, and techniques, the daily execution of these practices is ultimately up to the facility’s janitorial team. Our priority remains delivering the most effective and efficient cleaning methods for our clients’ floors.

Additionally, the Flotex flooring’s ability to conceal the soil we extracted is remarkable. This quality not only underscores Flotex’s durability and high performance but also its capacity to look clean, despite significant soil presence underneath.